Brush Machine Manufacturer for Broom, Brush, and Strip Machines.

Brush Machine Manufacturer

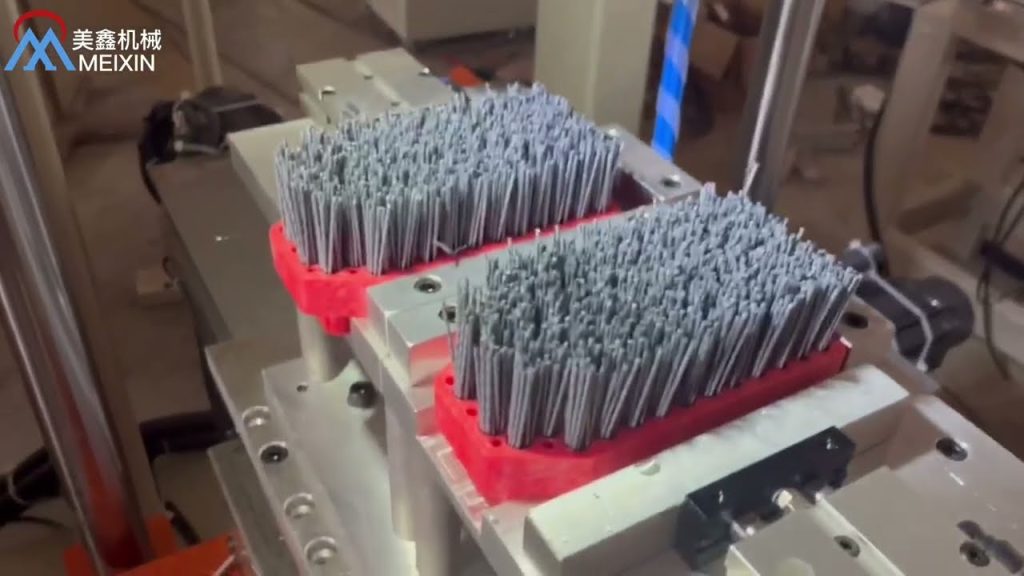

In the rapidly evolving world of industrial production, efficiency and precision are paramount. For businesses involved in the manufacturing of brooms, brushes, and strip products, having access to high-quality machinery is essential. As a leading Brush Machine Manufacturer Meixin Comb Brush Machinery has been at the forefront of providing innovative solutions that cater to diverse production needs. Our commitment to quality, reliability, and technological advancement ensures that clients can achieve superior results while optimizing operational efficiency.

Understanding the Role of a Brush Machine Manufacturer

A Brush Machine Manufacturer plays a critical role in the industrial sector by designing, producing, and supplying machinery that automates brush and broom production. These machines are essential for businesses looking to scale operations, reduce labor costs, and maintain consistent quality in their products.

Types of Machines Offered by a Brush Machine Manufacturer

A reputable Brush Machine Manufacturer typically offers a wide range of machines designed for different applications:

1. Broom Making Machines

Broom making machines are engineered to produce high-quality household and industrial brooms. They can handle various materials, including synthetic fibers, natural bristles, and wire, allowing manufacturers to diversify their product range efficiently.

2. Brush Making Machines

Brush making machines are versatile tools that create brushes for cleaning, cosmetic, or industrial purposes. A professional Brush Machine Manufacturer ensures these machines maintain precision, consistency, and durability.

3. Strip Brush Machines

Strip brush machines produce strip brushes used in doors, windows, and industrial machinery for sealing, cleaning, and guiding applications. These machines are designed for high efficiency and uniformity, minimizing waste and maximizing production speed.

Key Features to Expect from a Leading Brush Machine Manufacturer

Choosing the right Brush Machine Manufacturer is crucial for ensuring long-term productivity. Here are some of the key features and qualities to consider:

Precision Engineering

Precision is critical in brush and broom production. A top-tier Brush Machine Manufacturer provides machines engineered to exact specifications, ensuring every product meets quality standards.

Automation and Efficiency

Modern brush machines incorporate automation to reduce manual labor and increase production output. Automation not only speeds up manufacturing but also ensures consistent quality across batches.

Durability and Reliability

A reputable Brush Machine Manufacturer prioritizes the durability of its machines. High-quality materials, robust construction, and rigorous testing ensure that equipment remains operational for years with minimal maintenance.

Customization Options

Businesses often require specialized machines tailored to unique production requirements. Leading Brush Machine Manufacturers offer customization options to suit different materials, sizes, and production volumes.

Advantages of Partnering with a Professional Brush Machine Manufacturer

Collaborating with an experienced Brush Machine Manufacturer brings numerous benefits that can positively impact your business:

Enhanced Production Efficiency

Machines designed and manufactured by experts streamline the production process, reducing downtime and maximizing output. This efficiency allows businesses to meet market demand more effectively.

Consistent Product Quality

High-quality brush machines ensure uniformity in bristle placement, density, and overall finish. Consistency is key for maintaining brand reputation and customer satisfaction.

Cost Savings

While the initial investment in machinery may be significant, partnering with a reliable Brush Machine Manufacturer can result in long-term cost savings by reducing labor, material waste, and maintenance expenses.

Technical Support and After-Sales Service

Leading Brush Machine Manufacturers provide comprehensive technical support and after-sales service. This support includes installation, training, maintenance, and troubleshooting, ensuring that businesses can operate machines optimally.

Industry Applications of Brush Machines

Brush machines are versatile and find applications across various industries. A professional Brush Machine Manufacturer designs equipment to meet the demands of multiple sectors:

Household Cleaning Products

From brooms to scrub brushes, these machines enable the mass production of household cleaning essentials that meet consumer expectations for durability and performance.

Industrial Brushes

Industries such as automotive, electronics, and food processing rely on specialized brushes for cleaning, polishing, and assembly operations. A reliable Brush Machine Manufacturer ensures these machines can produce brushes that meet rigorous industrial standards.

Cosmetic Brushes

The beauty industry requires precision-engineered brushes for makeup application and personal care. Advanced brush machines allow manufacturers to produce high-quality cosmetic brushes efficiently.

Strip Brushes for Mechanical Applications

Strip brushes are widely used in machinery for sealing, guiding, and cleaning operations. Machines from a trusted Brush Machine Manufacturer produce strip brushes with accuracy and consistency, ensuring optimal performance in industrial environments.

Innovations in Brush Machine Manufacturing

Technological advancements continue to transform the brush manufacturing industry. A forward-thinking Brush Machine Manufacturer invests in research and development to introduce innovations that enhance productivity and quality.

Computerized Control Systems

Modern brush machines often feature computerized control systems that allow precise control over bristle placement, density, and trimming. This technology reduces human error and increases consistency.

Multi-Function Machines

Some machines are designed to handle multiple brush types and materials, offering flexibility for manufacturers looking to diversify their product offerings without investing in separate machines.

Eco-Friendly Production

Sustainable practices are becoming increasingly important in manufacturing. Leading Brush Machine Manufacturers develop machines that minimize waste, reduce energy consumption, and incorporate environmentally friendly materials.

How to Choose the Right Brush Machine Manufacturer

Selecting the ideal Brush Machine Manufacturer is a critical decision that impacts your production efficiency and product quality. Here are some factors to consider:

Reputation and Experience

Look for manufacturers with a proven track record in the industry. Established companies like Meixin Comb Brush Machinery have years of experience and a history of delivering reliable machines.

Technical Expertise

Ensure that the manufacturer has the technical expertise to design and build machines that meet your specific requirements. Their ability to innovate and customize solutions is a key differentiator.

Quality Assurance

A professional Brush Machine Manufacturer should adhere to strict quality control standards. This includes rigorous testing of machines to ensure performance, durability, and safety.

After-Sales Support

Reliable technical support and maintenance services are essential. The right manufacturer will provide training, troubleshooting, and spare parts to keep your operations running smoothly.

Conclusion

In conclusion, choosing the right Brush Machine Manufacturer is essential for businesses looking to excel in the broom, brush, and strip brush industries. High-quality machines enhance productivity, ensure consistent product quality, and provide long-term cost savings. Meixin Comb Brush Machinery stands out as a trusted provider, offering precision-engineered equipment, innovative solutions, and comprehensive support for businesses of all sizes. Partnering with a professional Brush Machine Manufacturer ensures that your manufacturing operations are efficient, reliable, and ready to meet the demands of a competitive market.