Custom Foam Inserts Pelican Cases for Industrial and Commercial Use

Introduction to Custom Foam Inserts Pelican Cases

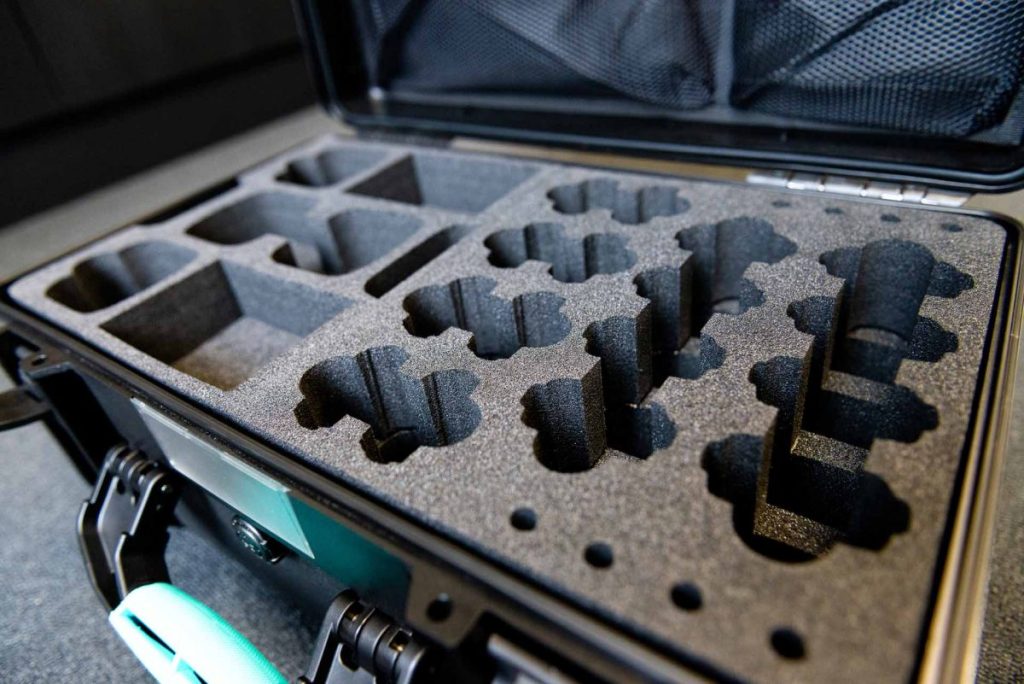

In today’s fast-paced industrial and commercial environments, protecting sensitive equipment during transport and storage is critical. Custom Foam Inserts Pelican Cases provide an ideal solution, combining durability with precision protection. These cases are engineered to withstand harsh conditions while offering customizable options for any type of equipment. Whether you are handling delicate electronics, specialized tools, or commercial devices, these foam inserts ensure that your valuables remain secure.

Advantages of Custom Foam Inserts Pelican Cases

Custom Foam Inserts Pelican Cases offer several advantages over standard protective solutions. One of the primary benefits is their ability to absorb shocks and prevent damage from impacts. Industrial and commercial equipment often faces rough handling and transportation hazards. With custom foam inserts, each device is securely cushioned to prevent scratches, dents, or breakage. Additionally, these cases are waterproof and dustproof, providing complete protection in demanding environments.

Tailored Protection for Industrial Equipment

Industrial operations require transporting expensive and sensitive equipment safely. Custom Foam Inserts Pelican Cases can be designed to match the exact dimensions of your tools and machinery. This level of customization ensures that each component fits snugly within the foam, minimizing movement during transit. From precision instruments to heavy machinery parts, these cases provide a reliable solution that industrial companies trust for long-term protection.

Commercial Applications of Custom Foam Inserts Pelican Cases

Commercial businesses benefit greatly from using Custom Foam Inserts Pelican Cases. Retailers, photographers, and technical service providers can store and transport their equipment safely. Customized foam inserts prevent items from shifting, reducing the risk of damage and loss. This not only protects valuable assets but also reduces replacement costs, making these cases a cost-effective solution for businesses of all sizes.

Materials and Construction

The quality of Custom Foam Inserts Pelican Cases depends on the materials used. Typically, high-density polyethylene or polyurethane foam is chosen for its resilience and cushioning capabilities. These materials absorb impact efficiently while remaining lightweight for easy transportation. Pelican cases themselves are known for their rugged construction, and when paired with custom foam inserts, they provide an unmatched level of security for industrial and commercial applications.

Easy Customization Options

One of the most significant advantages of Custom Foam Inserts Pelican Cases is their flexibility. Companies can request foam inserts tailored to specific equipment shapes and sizes. CNC cutting, die-cutting, and laser shaping techniques allow precise foam design to fit your needs. From single-item compartments to complex multi-tiered layouts, customization ensures optimal protection for each piece of equipment.

Enhancing Efficiency in Industrial Settings

By using Custom Foam Inserts Pelican Cases, industrial facilities can enhance operational efficiency. With equipment securely organized within foam compartments, workers can quickly access tools and instruments without wasting time searching. Custom inserts also reduce the risk of errors and accidents, as each item has a designated place, making workflow smoother and safer.

Durability and Longevity

Durability is a key factor in choosing Custom Foam Inserts Pelican Cases. These cases are designed to endure extreme temperatures, rough handling, and environmental stress. Foam inserts maintain their shape and protective qualities over time, ensuring long-lasting equipment safety. For commercial and industrial users, this durability translates into lower replacement costs and reliable performance throughout the lifecycle of the equipment.

Cost-Effectiveness and Value

Investing in Custom Foam Inserts Pelican Cases is cost-effective in the long run. While the initial investment might be higher than generic cases, the protection provided reduces repair and replacement expenses. Businesses save money by preventing equipment damage, downtime, and lost productivity. Additionally, the adaptability of custom foam inserts ensures that your investment continues to provide value even as equipment needs evolve.

Applications Across Industries

Various industries rely on Custom Foam Inserts Pelican Cases to safeguard their equipment. Aerospace, medical, photography, electronics, and manufacturing sectors all benefit from these protective solutions. Whether transporting delicate instruments, industrial tools, or high-value commercial devices, custom foam inserts provide peace of mind and operational efficiency.

Conclusion

Custom Foam Inserts Pelican Cases are essential for industrial and commercial users seeking maximum protection for their valuable equipment. With tailored designs, high-quality materials, and durable construction, these cases ensure your equipment remains safe from impact, moisture, and environmental hazards. Investing in custom foam inserts enhances efficiency, reduces replacement costs, and provides a reliable solution for years to come. For businesses that prioritize equipment protection and operational efficiency, Custom Foam Inserts Pelican Cases are the ultimate choice.